Sealing Air Ducts reduces heat loss

Sealing Air Ducts reduces heat loss

Related Links

Insulating

Framing

Energy Star Designs

Forced Air Distribution Systems

ENERGY STAR FORCED AIR DISTRIBUTION SYSTEMS

- All doors and covers on the air handler must be in place.

- Plenum connections to the air handler must be leak free.

- All filter racks must have leak free filter rack covers.

- There should be no return grilles drawing from a cellar, attic, garage,

the outdoors, or any other unconditioned area.

- When closed, any supply grilles in unconditioned or tempered spaces (such

as basements or garages) must be securely installed and leak free when closed.

- All duct connections including: joist panning, straight joints, round

ducts, rectangular ducts, boots, T's, Y's, L's, plenums, take offs, and air

handlers on supply and return sides, must be sealed.

- Every effort should be made to design the duct system to run within the

conditioned area. When not possible, the duct cavity should be insulated with

rigid foam caulked in place. In 2X4 walls, one inch of foil faced R-max type

insulation should be used. In 2X6 walls, two inch should be used.

- All supply runs through unconditioned areas should be installed so that

they have room for additional insulation on all sides. The standard R-4 wrap

by itself is unacceptable.

- Exhaust ducts running through unconditioned space must be insulated and

have a minimum 1/4" rise for every foot of run.

- Kitchens must have an exhaust fan that vents to the outside.

- There must be mechanical ventilation of at least 90 cfm with a sone rating

of 1.5 or below and controlled by a timer switch.

- Heating units should be sealed combustion and 90% efficient or better.

- Thermostats should not be located in rooms with fireplaces.

MATERIAL AND APPLICATION GUIDELINES

- Clean duct surface to remove oil residue.

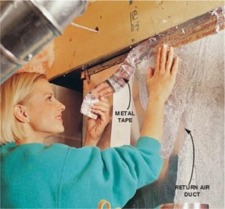

- Apply mastic designed for the type of duct being installed or apply foil

tape with asphalt type backed adhesive.

- Mastic can also be applied with a caulking gun, where applicable.

- Coat entire joint/connection with a continuous strip of mastic. Spread

mastic at least one inch on each side of joint/connection. Mastic should be

thick enough to hide metal surface of duct - about 1/16" thick.

- Duct tape is never acceptable.

|